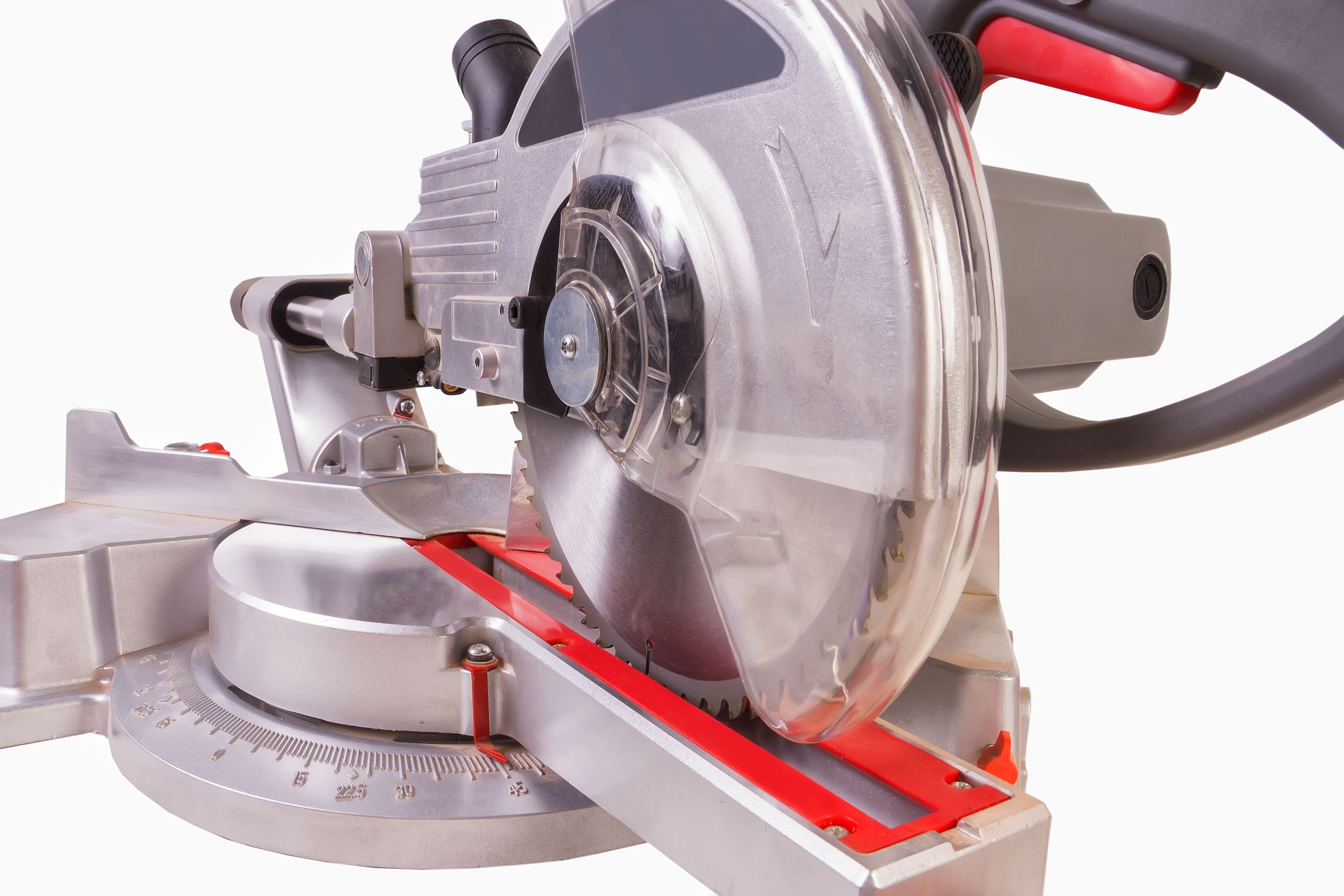

Amputations are some of the most serious and debilitating workplace injuries. They are widespread and involve a variety of activities and equipment. Amputations occur most often when workers operate unguarded or inadequately safeguarded mechanical power presses, power press brakes, powered and non-powered conveyors, printing presses, roll-forming and roll bending machines, food slicers, meat grinders, meat-cutting band saws, drill presses, and milling machines as well as shears, grinders, and slitters.

What types of machine components are hazardous? The following types of mechanical components present amputation hazards:

- Point of operation—the area of a machine where it performs work on material.

- Power-transmission apparatuses— flywheels, pulleys, belts, chains, couplings, spindles, cams, and gears in addition to connecting rods and other machine components that transmit energy.

- Other moving parts—machine components that move during machine operation such as reciprocating, rotating, and transverse moving parts as well as auxiliary machine parts.

What can employers do to help protect workers from amputations? You should be able to recognize, identify, manage, and control amputation hazards commonly found in the workplace such as those caused by mechanical components of machinery, the mechanical motion that occurs in or near these components, and the activities that workers perform during mechanical operation. Work practices, employee training, and administrative controls can help prevent and control amputation hazards.

This 4-hour course covers the types of machine guarding, importance of safeguarding places where most machine hazards occur, and safety control devices.